Advanced Ignition Method for Combustion Engines

Advanced Ignition Method for Combustion Engines

Propulsion Technology for UAVs

Sustainable Aviation

Prechamber Jet Ignition for Internal Combustion Engines

Pre-chamber jet ignition, an alternative to traditional spark ignition, has been used in large-bore natural gas engines and F-1 racing cars. It has demonstrated the potential for enabling stable ultra-lean combustion, reduction in cycle-to-cycle variation, and extension of the lean operating limit of the engines. The concept of pre-chamber jet ignition is to burn a small amount of near-stoichiometric air-fuel mixture in a small volume called pre-chamber. The higher pressure resulting from pre-chamber combustion pushes the combustion products into the main chamber in the form of a hot turbulent jet, which then ignites the lean mixture in the main chamber. Compared to standard spark ignition, the hot jet has a much larger surface area leading to multiple ignition sites on its surface, which can enhance the probability of successful ignition and cause faster heat release and flame propagation due to the strong turbulence contained in the jet.

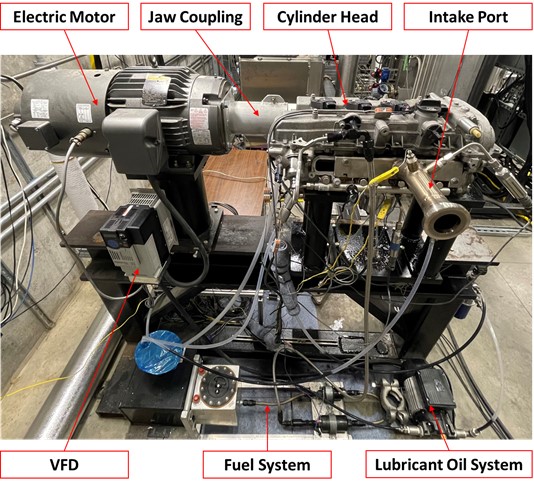

PRIME Rig (Pre-chamber Research In Modified Gasoline Engine)

- The PRIME rig is a modified version of GM LTG four-cylinder SI gasoline engine. With the use of a real gasoline engine as the base for the experimental setup, we are able to maintain the complex configurations of an engine, such as the novel geometry of the pent roof cylinder head, while operating the valve trains continuously at desired engine speeds. Unlike tests using a rapid compression machine, where the fuel/air mixture is charged only once for studying a single jet ignition and combustion event, the present setup is able to run and test continuously for many cycles, which enables us to examine cycle-to-cycle variations as well as residual effect.

- The PRIME rig is capable of running up to 4000 RPM and supplying high-pressure, high-temperature Air or Air/N2 mixtures up to 30 bar and 800 K. This enables us to conduct tests at different load conditions as well as to simulate different EGR dilution operations.

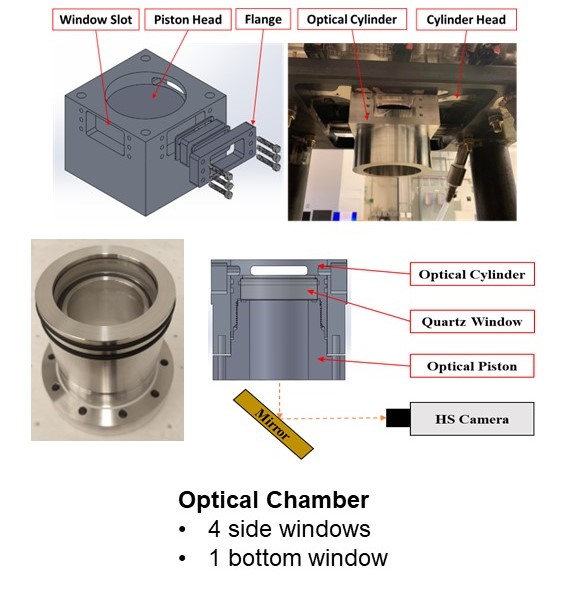

- High speed infrared camera (up to 3,000 Hz) and video camera (up to 20,000 Hz), along with optically accessible cylinder and piston, enabled us to apply high-speed imaging diagnostics for the visualization of jet penetration and ignition processes inside the main cylinder.

- High frequency pressure sensor (Kistler 6052) records the pressure history of the main cylinder over cycles.

Optically accessible cylinder and piston

Prechambers